Built To Perform

Precision CNC Machining and CNC Prototyping Services

-

British, Danish & South African

Owned

-

ISO9001 & ISO13485

Certified

-

Full DFM & Global Technical

Support

-

No MOQ/MOV & Exceptional

Customer Satisfaction

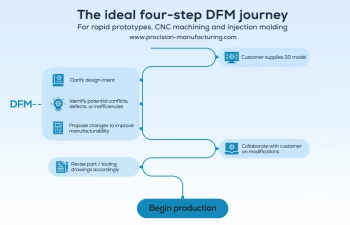

How to Start Your CNC Machining Project

Step 1

Upload Design

Begin your project by selecting a manufacturing process and uploading your design file.

Step 2

Quote & DFM

Step 3

Manufacturing

Step 4

Shipping

CNC Machining Services: From Concept to Reality

Procision Manufacturing – CNC

Custom Precision CNC Machining Services

Your projects demand precision, quality, and fast turnaround — and that’s exactly what you’ll get with Procision. Whether you’re rapid prototyping a groundbreaking product or scaling up for full production, our custom CNC machining services ensure every part is crafted to your exact specifications.

Request your CNC machining quote today and take the first step toward flawless results.

Procision Manufacturing – CNC

Applications of Precision CNC Machining Services

By combining technical depth with manufacturing agility, our CNC precision machining ensures your parts meet the highest standards — every time.

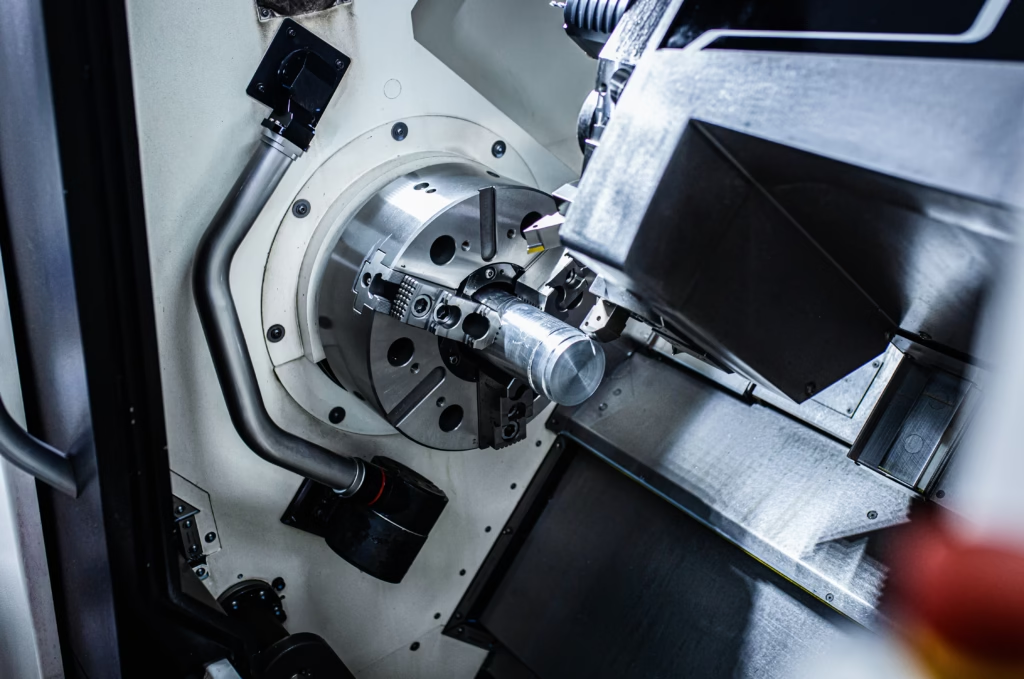

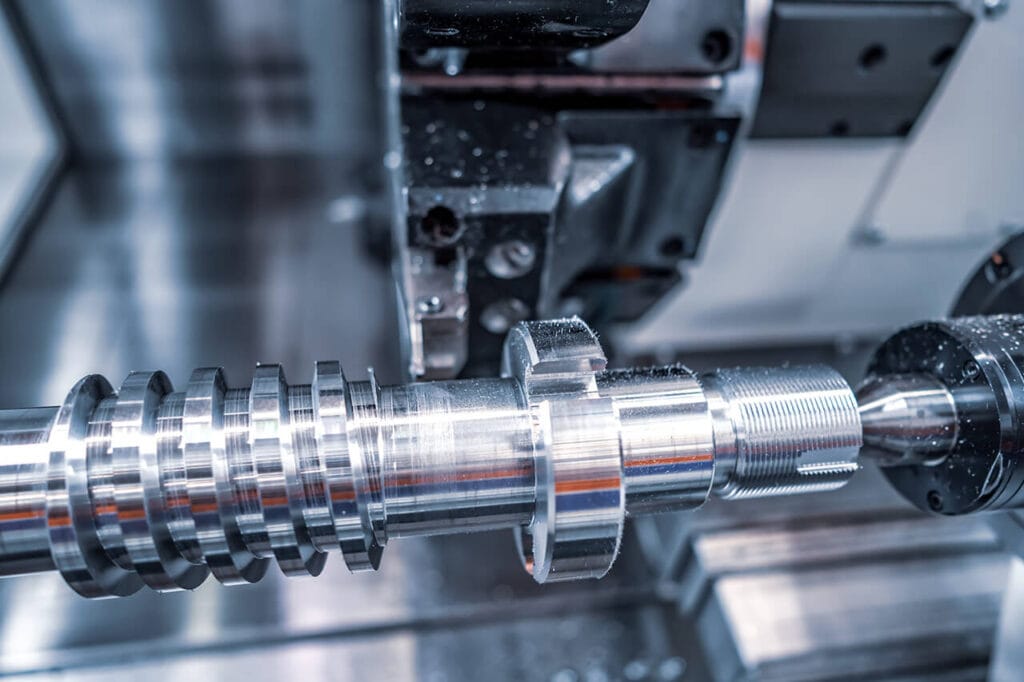

When your parts demand deep bores, fine threads, or true cylindrical symmetry, our CNC turning services deliver high precision, excellent surface finishes, and fast throughput in any volume.

CNC milling is used to produce prismatic and geometrically complex parts with tight tolerances and smooth finishes.

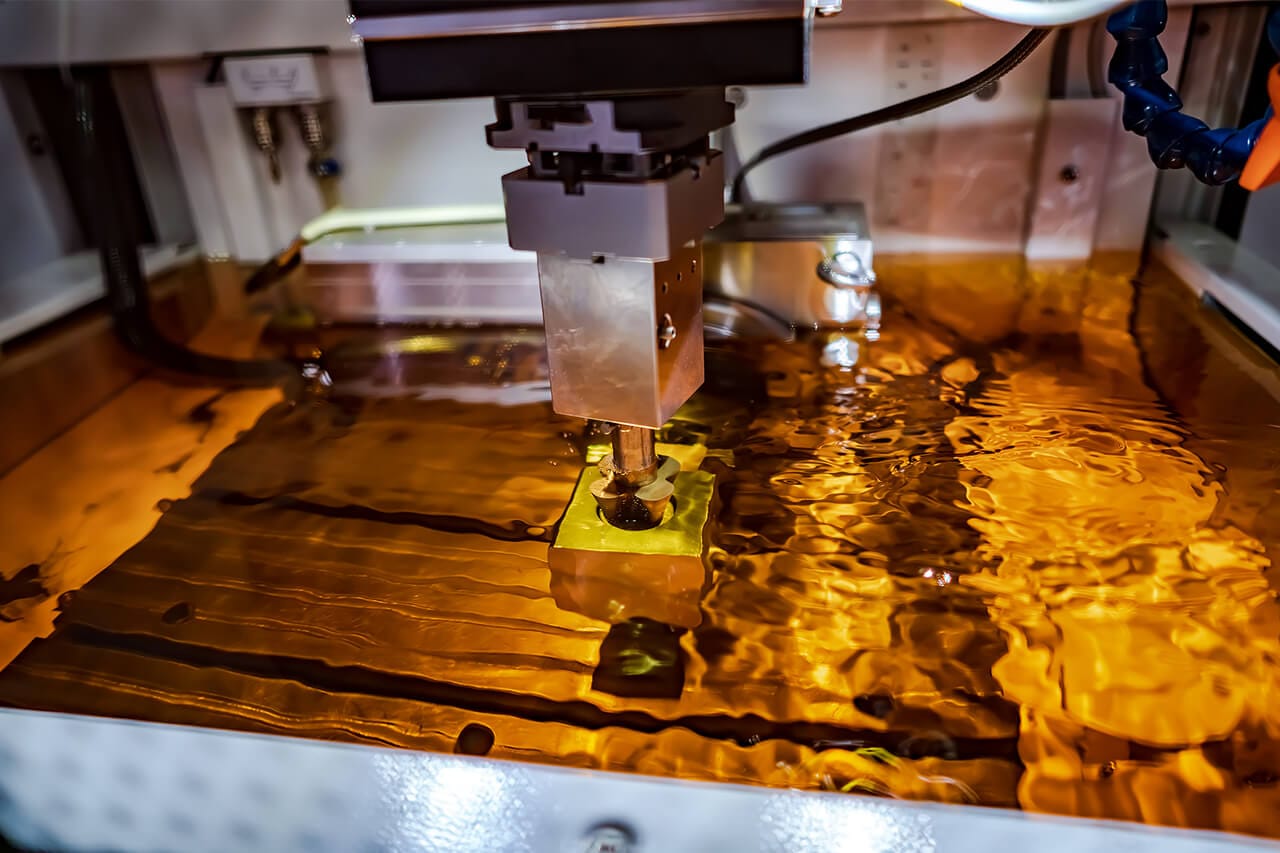

EDM Services

Machine intricate cavities in hardened steel featuring sharp right angles using electrical discharge machining (EDM). Ideal for mold making and specialty tooling — no post-processing required.

Rapid Tooling Services

Accelerate your product development. Our rapid tooling capabilities deliver fast, accurate mold tooling for injection molded parts — perfect for low-volume production and iterative prototyping.

Why Choose Us?

Why Choose Our Precision CNC Machining Services?

Your success depends on a reliable custom parts manufacturer who delivers, and here’s what you can expect:

Trusted. Transparent. Technically Elite

As a forward-thinking CNC machining supplier, we’ve built our platform around what matters most to you: accuracy, clear communication, material control, and rapid response.

In-House CNC Machining Equipment

State-of-the-art 5 axis CNC machining centers, integrated CAD/CAM workflows, and premium tooling systems.

Extensive Material Selection

CNC machining works with a wide range of metal alloys, plastic resins and composites. Contact us to speak directly to a sales engineer about your needs.

Material Verification & Compliance

Positive Material Identification (PMI) guarantees every raw material meets your specifications and regulatory requirements.

Tight CNC Machining Tolerances

Production-Ready Finishes

Choose from professional painting, anodizing, media blasting, hand and machine polishing, laser etching, plating, and more — for ready-to-ship results.

Ready to Start Your CNC Machining Project?

We are a team of technical professionals ready to assist you.

Why Choose Us?

CNC Prototyping Service Applications

CNC machining is a great solution for making high-quality rapid prototypes. Here are the most common applications:

Design iteration

Create multiple copies of your initial design at minimal cost, so you can refine the look and feel before committing to production tooling.

Crowdsourcing

Build marketing campaigns and generate investor interest by creating showroom-quality design mockups.

Proof-of-concept

Physical prototypes help to verify that you’re on target to achieving your development goals, and they can also show you where you need to make modifications.

Engineering testing

Some prototypes are strong and robust enough to allow for real-world functional testing and approval.

Bridge to production

CNC machining can be used to make a handful of prototypes quickly and cost-effectively as a bridge to later full-scale production when your market is mature.

Advantages of Our CNC Machining Services

When you need consistent performance — and zero compromise — trust Procision’s CNC machining services to deliver.

Unmatched Accuracy

Produce complex geometries with extreme precision

Material Versatility

Metals, plastics, and advanced composites

Speed & Efficiency

Minimize tooling investment while maximizing throughput

Superior Surface Quality

Eliminate the need for secondary processing

Consistency at Scale

Seamless transition from prototype to production

No Volume Limits

Flexible support for small batches or large production runs

Common Questions

Precision CNC Machining Services FAQ

Find answers to common questions about CNC machining services and how industries like medical, electronic, agriculture, and consumer products can achieve their goals by working with Procision.

What are CNC machining services?

CNC machining is an subtractive manufacturing,using computer-controlled tools to remove material and produce end-use parts from metal, plastic, or composites. At Procision, we specialize in precision 5 axis cnc machining, cnc milling parts, cnc turning parts, and EDM processes.

How does the CNC machining process work?

Once we receive your CAD file, our engineers will perform a comprehensive design review before generating the fastest and most efficient toolpaths for performance, speed and cost-savings.

When to use CNC machining?

Custom product developers choose CNC machining for rapid prototypes and end-use parts when they value speed, accuracy, and versatility and minimal setup costs.

CNC machining vs 3D printing?

CNC machining is typically faster and more cost-effective for metal parts. It’s ideal for tight tolerances and high-strength materials. 3D printing excels at highly complex internal geometries not machinable via traditional methods.

What materials can be machined?

Our machines support:

- Metals: Aluminum, titanium, copper, stainless steel, magnesium, Inconel

- Plastics: PEEK, PTFE, polycarbonate, acetal, and more

- Composites: Carbon fiber and specialty blends

What tolerances can you meet?

Standard tolerances are ±0.01 mm. We can support tighter tolerances as needed — just ask.

What factors affect CNC machining costs?

Cost depends on part complexity, material selection, volume, and finish requirements. Get a quote tailored to your project.

How do I get a quotation?

Upload your drawings and specifications to the Procision Manufacturing team. We will analyze all the project details and deliver an accurate quotation quickly.

Let's Build What's Next - Together

Whether you’re building one part or one million, the Procision team delivers consistent results — on time, to spec, and built to perform. Request a quote today and discover what a responsive, professional CNC machining manufacturer can do for you.