What’s the Role of a Mold Tool?

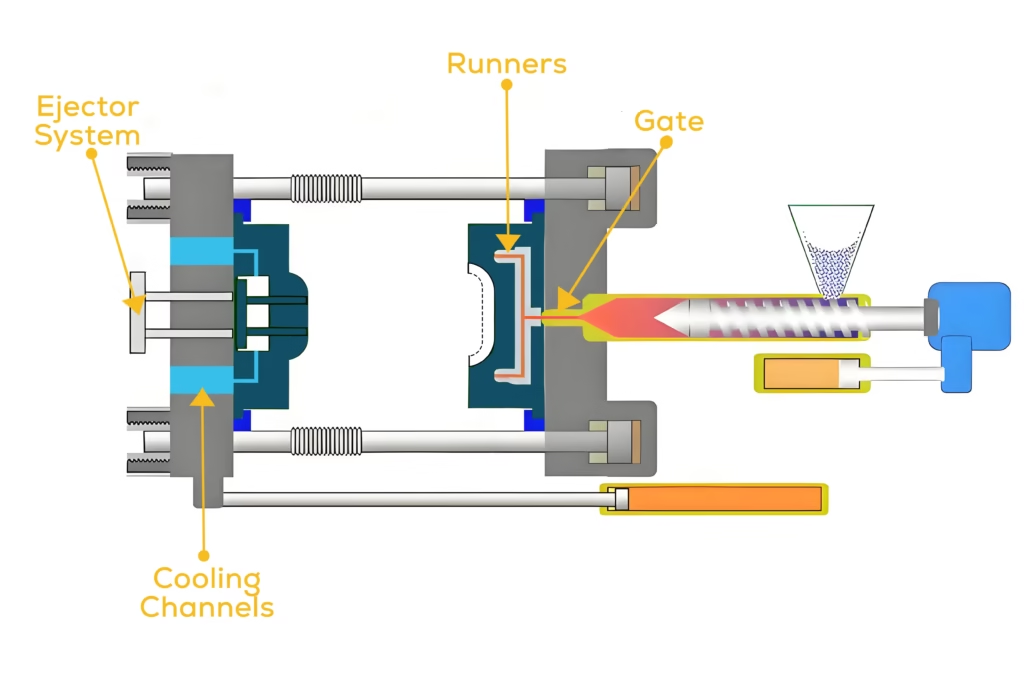

To mold a part, you need a mold. This mold — sometimes called a “tool” or “die” — defines the exact geometry of the plastic part and enables mass production.

Molds typically consist of two halves: a core side and a cavity side, both starting as solid blocks of aluminum or steel. These blocks are precisely machined to form a negative of the final part, along with complex internal features such as:

- Gates and runners to direct molten plastic

- Cooling channels to regulate temperature and cycle times

Ejector systems to remove the molded part cleanly

How Are Mold Tools Made in 2025?

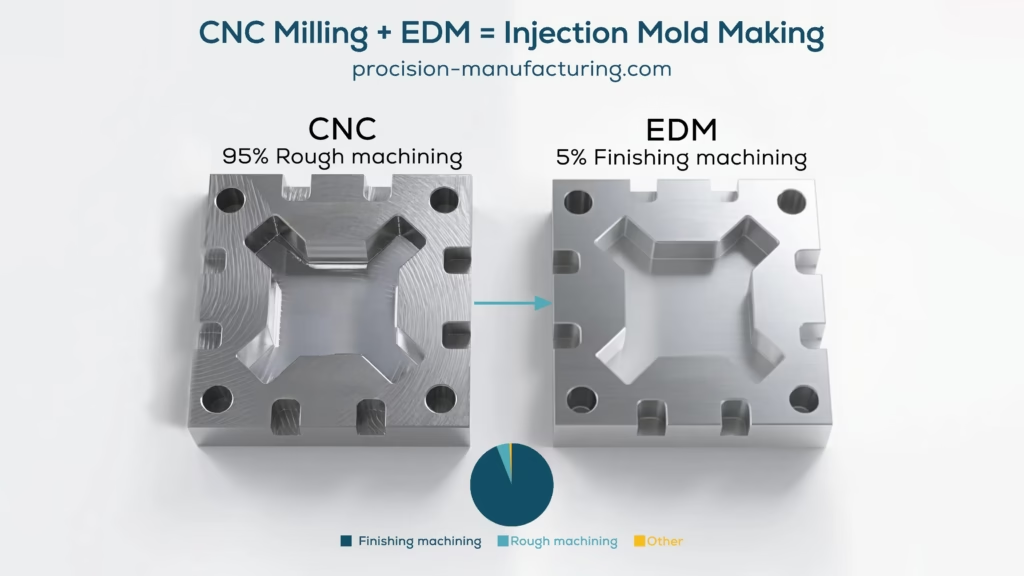

Modern mold tools are fabricated using two complementary digital manufacturing methods:

- CNC Milling: High-speed rotating cutters remove bulk material with tight tolerances.

EDM (Electrical Discharge Machining): Uses electrical discharges to erode metal, ideal for intricate and inaccessible features.

What Are the Limitations of CNC Milling?

CNC milling process is the workhorse of toolmaking, handling 90–95% of the mold making job. But it’s not a silver bullet. Here’s where it falls short:

- Line-of-sight limitation: Undercuts and hidden features are inaccessible to milling tools.

- Limited depth reach: Deep pockets or bores may exceed spindle travel or cutter length.

- Rounded internal corners: End mills impart a radius; they can’t make true sharp corners.

Post-processing: Surface tool marks often require hand polishing for finish quality.

How Does EDM Complement CNC Milling?

EDM excels where CNC hits a wall. It uses custom-shaped electrodes to erode complex geometries with zero cutting force. Key advantages include:

- Sharp internal corners with high dimensional accuracy

- Excellent surface finish straight from the machine

- Deep, narrow features like ribs or vents with minimal deflection

Compatibility with hardened steels, such as H13, S7, and other high-performance alloys used in injection mold making

Are There Alternatives to CNC Milling and EDM?

A few niche alternatives exist, such as 3D-printed molds using high-temperature photopolymers or sintered metals. But these are best reserved for rapid prototyping or short runs manufacturing.

What About Manual Toolmaking?

Manual mold making — using bridgeport mills and hand finishing — was once the industry standard. But it’s labor-intensive, inconsistent, and hard to scale.

An All-in-one Solution For Streamlined Production

Ready to Start Your Next Mold?

- Book a discovery call

- Upload your CAD files for a free, no-obligation quote