From Prototyping To Mass Production

Micro Injection Molding Services

-

British, Danish & South African

Owned

-

ISO9001 & ISO13485

Certified

-

Full DFM & Global Technical

Support

-

No MOQ/MOV & Exceptional

Customer Satisfaction

Procision Micro Molding

Is Micro Molding The Right Fit For You?

Procision Micro Molding

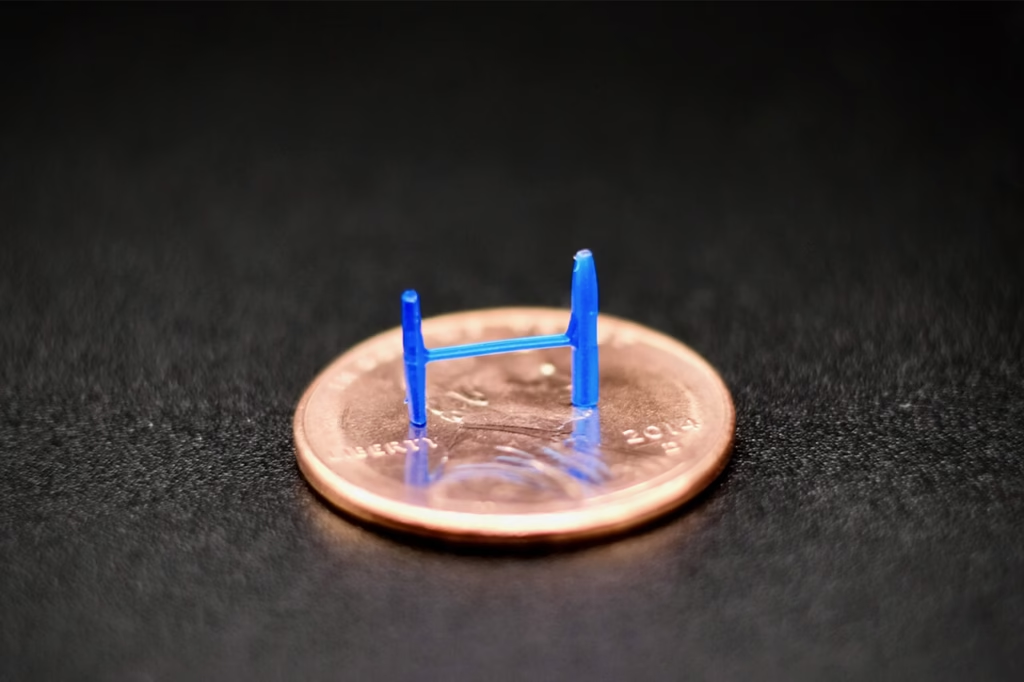

Micro Injection Molding Services: Precision Parts You Can Rely On

Micro injection molding is the most advanced way to produce ultra-small plastic parts with tight tolerances. The secret is controlling heat inside many small cavities packed closely together. This is only possible using precise digital microcontrollers.

Benefits of Micro Injection Molding

Here’s how micro-injection molding addresses your most pressing challenges:

Exceptional precision for tiny features:

Micro injection molding is the most advanced way to produce ultra-small plastic parts with tight tolerances. The secret is controlling heat inside many small cavities packed closely together. This is only possible using precise digital microcontrollers.

Lower material use, less waste:

Small shot sizes using the micro injection molding process reduce scrap and help control material cost.

Scalability for diverse production needs:

Micro injection molding is suitable for both small production runs and large-scale manufacturing, providing flexibility for various project demands.

Compatibility with advanced materials:

The process supports hundreds of plastic resins and a wide range of innovative materials. They include high-performance polymers and biocompatible resins, expanding its application across industries such as medical, electronics, aerospace and automotive.

Faster changeovers and throughput:

Compact barrel systems can reduce purge/cleaning time during material changes and support quicker turnaround.

Potentially lower tooling cost and lead time:

The smaller scale of micro molds reduces the tooling investment by about 40%. It may also reduce machining time compared with conventional tooling.

Procision Manufacturing

Applications For Micro Molding Injection

Micro injection molding is suitable for many industries that prioritize precision, weight reduction and repeatability on the small scale. Applications include:

- Medical devices: Implants, wearables

- Electronics: Smartphones, sensors

- Robotics: Lightweight, durable components

- Consumer Products: Accurate components for everyday devices

Micro injection molding is the ideal choice when you need consistent, reliable precision and accuracy you can trust.

Micro Injection Molding Specifications

Injection Molding workshop

All micro injection molding is conducted in our ISO Class 8 clean room to support medical and electronic components manufacturing.

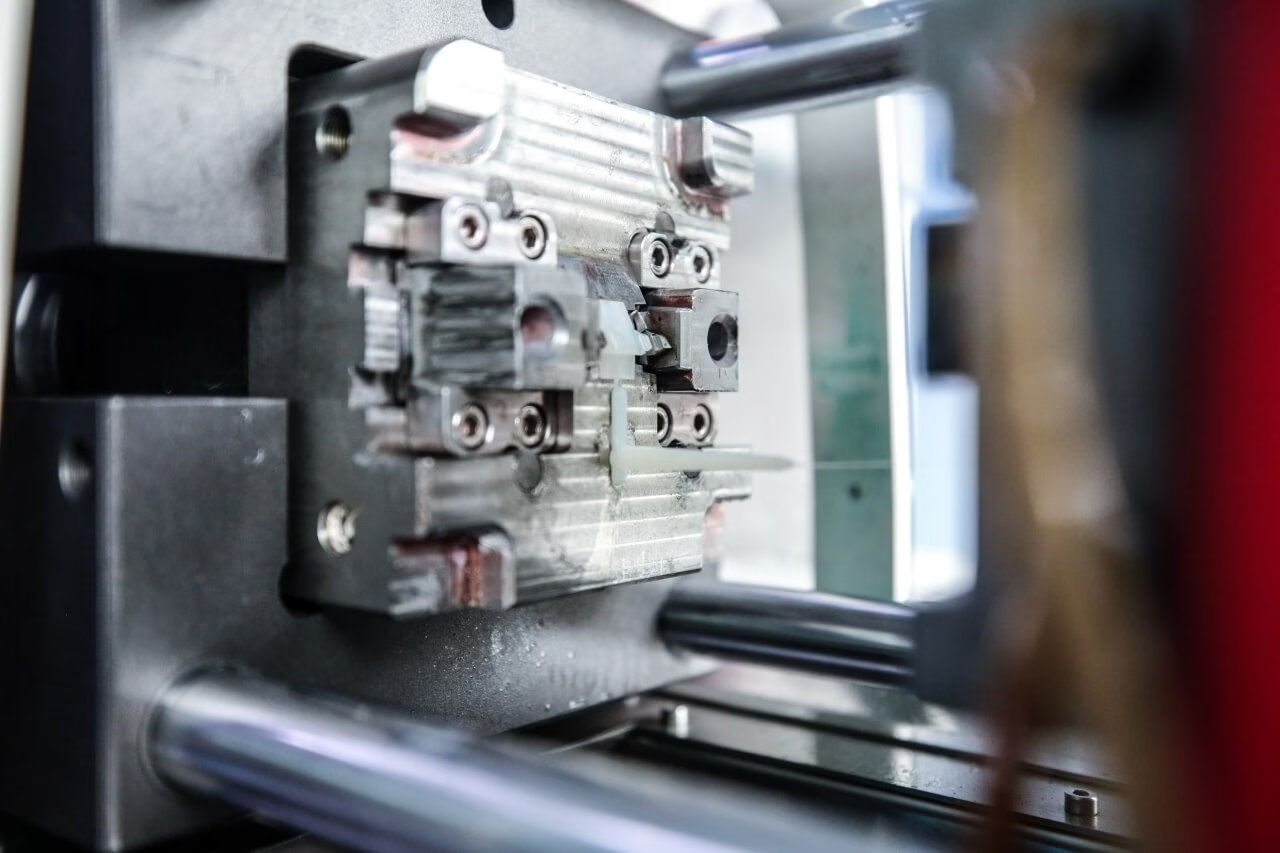

Molding Equipment

- Two vertical benchtop micro injection molding machines

- Clamp force: 10 tons

- Drive system: Hydro-electric

Molding range

- Shot size: 12 cm³

- Max part size(typical): 150 × 150 × 100 mm

- Min part size(typical): 2 × 2 × 1 mm

Precision

Tolerance: ±0.01 mm (application-dependent)

Process control & connectivity

- Stores 1,000+ molding parameter sets

- Wi-Fi and LAN enabled

Design for Manufacturability (DFM) Capability

| Category | Focus Area | Description |

|---|---|---|

| Design Guidelines | Wall Thickness Uniformity | Evaluate wall thickness consistency to prevent defects such as shrinkage or warpage caused by abrupt transitions or overly thick sections. |

| Fillets & Corners | Review all corner transitions to ensure appropriate radii are applied, minimizing stress concentration and enhancing moldability. | |

| Draft/Rib Angles | Verify that ribs and textured areas comply with minimum draft angle standards to support smooth part ejection and surface integrity. | |

| Tooling Layout | Gate Placement Strategy | Assess gate type and location to optimize flow balance and avoid surface defects, ensuring efficient and aesthetic material injection. |

| Ejector Pin Layout | Analyze ejector pin layout to ensure uniform ejection force and to avoid visible or functional damage to the final part. | |

| Runner Balancing | Review runner design to confirm balance across multiple cavities, promoting consistent fill and reduced variation. | |

| Simulation Integration | Mold Flow Simulation | Conduct mold flow simulations to predict and address potential issues such as weld lines, air traps, sink marks, and uneven cooling. |

| Design of Experiments (DOE) | Apply Design of Experiments (DOE) methodology to fine-tune mold parameters, reducing variation and enhancing process repeatability. | |

| Sensor Feedback Integration | Integrate sensor feedback and process window controls to maintain stable production conditions and proactively address deviations. | |

| Quality & Compliance | Part Marking & Traceability | Ensure product traceability and compliance by planning for part engravings, markings, and insert requirements during the design phase. |

ISO Class 8 Clean Room

| Test Parameter | ISO Class 8 Requirement | Measured Result | Conclusion |

|---|---|---|---|

| Particle Count (≥0.0005mm) | ≤3,520,000 particles/m³ | 198,916 particles/m³ | Compliant |

| Particle Count (≥0.005mm) | ≤2,930,000 particles/m³ | 1,272 particles/m³ | Compliant |

| Air Velocity (m/s) | >0.25 | 2.16 | Compliant |

| Temperature | 18~28°C | 21.75°C | Compliant |

| Relative Humidity | 45%~65% | 53.39% | Compliant |

| Pressure Differential (Pa) | > 10 | 30.4 | Compliant |

| Noise Level (dBA) | ≤65 | 62.6 | Compliant |

| Illuminance (lx) | ≥200 | 366 | Compliant |

| Settling Bacteria (φ90mm, 30min) | ≤3 CFU/plate | 2.5 CFU/plate | Compliant |

| Airborne Viable Particles | ≤100 CFU/m³ | 16.5 | Compliant |

Ready To Start Your Project?

Our team of technical professionals are ready to assist.

Common Questions

Procision Micro Injection Molding Service FAQ

Find answers to common questions about micro plastic injection molding services, mold design, and how these services help industries like medical, electronic, agriculture, and consumer products achieve their goals.

What is micro injection molding?

Like its conventional counterpart, micro injection molding works by injecting liquid plastic resin into a mold cavity under pressure, where the material is cooled to form a solid plastic part. The difference lies in the small size of the gates, runners and cooling channels, which demands much finer temperature and pressure control to maintain accuracy and consistency for miniature parts.

What are the advantages of micro injection molding?

The benefits of micro injection molding include reduced tooling costs, shorter production lead times, faster cycle times, reduced material consumption and waste, and tight tolerances on a micro scale.

How do you calculate the cost of micro injection molding?

Micro injection molding costs are calculated as the sum of four primary components:

- Material cost – Plastic resin, mold release agent and tooling raw material, all of which are much lower than with conventional injection molding.

- Direct labor: Toolmaking, testing, production – any task that adds value to the product.

- Indirect labor: Engineering design, packing and shipping, administration.

- Overhead: Insurance, utilities, plant maintenance, tax, etc.

How durable are micro injection molding tools?

The tools used in micro injection molding are made from the same durable steels as those of conventional molding. However, they are likely to last much longer because of the reduce injection pressures and lower heat build-up.

How do I get micro injection molding services?

Getting started is easy. Simply upload your 2D drawings and 3D CAD files, and our team of engineers will provide a detailed quotation right away. Upon order approval, you’ll receive clear communication and transparency and every production stage, along with full traceability documentation and quality inspection reports.

Here’s what makes us the preferred partner for small-scale plastic part manufacturing and how we will meet your micro molding needs.

Why Choose Us

Why Choose Procision for Micro Molding

When accuracy, quality, and reliability are non-negotiable, Procision Manufacturing delivers micro molding solutions you can trust. If you’ve been burned by unreliable suppliers, struggled with inconsistent quality, or faced delays, our team is here to ensure your micro molding project is a success.

Here’s what makes us the preferred partner for small-scale plastic part manufacturing and how we will meet your micro molding needs:

Proven Track Record of Success

With years of experience and a strong reputation for quality, our clients trust us to solve their most complex molding challenges. From rapid prototyping to full-scale production, you can count on us to deliver on-time, on-budget results every time.

Seamless Communication for a Smooth Experience

Transparent communication is critical to your project’s success. Our team works with you every step of the way, providing clear updates, real-time responses, and full support throughout the manufacturing process.

Certified Quality Assurance

Certifications like ISO 9001, 14001, and 13485 ensure the highest international standards for quality, environmental responsibility, and regulatory compliance. You can trust us with your most critical micro molding projects.

Flexible, Scalable Solutions

Whether you need a small batch or a large production run, micro injection molding offers flexibility. With services scaled to fit your needs, you get the right amount of parts when you need them.

Procision Manufacturing

Micro Molding

Micro molding service feature:

- Precise temperature and pressure control: Ensuring consistent results and maximum efficiency.

- Cost-effective steel tools: Up to 40% less expensive than full-sized alternatives.

- Digital process parameters: For consistency and fast set-ups.

- Fully electrical drive: This makes Babyplast machines fast and clean, so they are suitable for use in cleanroom environments such as the one at Procision Manufacturing.

These injection molding machines exemplify the quality and efficiency your project requires.

Considering Micro Molding for Your Next Project?

Ready to get your project off the ground? Request a free quote and let’s discuss your micro molding needs today! We’re here to help you with fast, reliable, and accurate manufacturing for your next part or project.