Precision Aluminum CNC Machining Services

- ISO-Certified

- Fast Lead Times

- Tight Tolerance Machining

-

No MOQ/MOV & Exceptional

Customer Satisfaction

Step 1

Upload Design

Begin your project by selecting a manufacturing process and uploading your design file.

Step 2

Quote & DFM

Step 3

Manufacturing

Step 4

Shipping

Aluminum Machining Material Overview

Aluminum alloys are used across various industries due to their versatility and ability to meet specific application requirements, such as strength, corrosion resistance, or formability. The choice of alloy should always be based primarily on the intended application of the finished part and the environment in which it will be used. Note that there may be more than one suitable choice.

CNC Machining Material Application

Common applications of aluminum span industries such as aerospace, automotive, marine, and more, making them essential materials for a variety of real-world uses. This chart provides a basic overview, but you should contact us directly to speak to a sales engineer to determine the best fit for your project.

Aluminum Alloy CNC Applications & Machining Guide

| Material Group | Material Name | Density (g/cm3) | Hardness (Brinell) | Tensile Strength (MPa) | Weldability | Machinability % |

|---|---|---|---|---|---|---|

| Aluminum | 1100-H112 | 2.8 | 23 | 90 MPa | Good | 50% |

| Aluminum | 2014-T6 | 2.8 | 120 HB | 483 MPa | Poor | 70% |

| Aluminum | 2024-T3 | 2.78 | 120 HB | 470 MPa | Poor | 45% |

| Aluminum | 2024-T351 | 2.78 | 120 HB | 470 MPa | Poor | 45% |

| Aluminum | 5052-H112 | 2.7 | 60~80 | 193 MPa | Good | 60% |

| Aluminum | 5052-H32 | 2.8 | 70~90 | 228 MPa | Good | 65% |

| Aluminum | 5083-H112 | 2.8 | 95 - 115 HB | 275 MPa | Yes | 55% |

| Aluminum | 6060-T6 | 2.8 | 80 | 190 MPa | Yes | 70% |

| Aluminum | 6061-T6 | 2.8 | 95 HB | 310 MPa | Excellent | 65% |

| Aluminum | 6061-T651 | 2.8 | 95 HB | 310 MPa | Excellent | 65% |

| Aluminum | 6063-T6 | 2.8 | 73 HB | 245 MPa | Excellent | 75% |

| Aluminum | 6082-T6 | 2.8 | 89 HB | 330 MPa | Good | 70% |

| Aluminum | 6082-T651 | 2.8 | 89 HB | 330 MPa | Good | 70% |

| Aluminum | AL7075-T6 | 2.81 | 150 HB | 570 MPa | Poor | 45% |

| Aluminum | AL7075-T651 | 2.81 | 150 HB | 570 MPa | Poor | 45% |

Ready To Start Your Project?

We are a team of technical professionals ready to assist you.

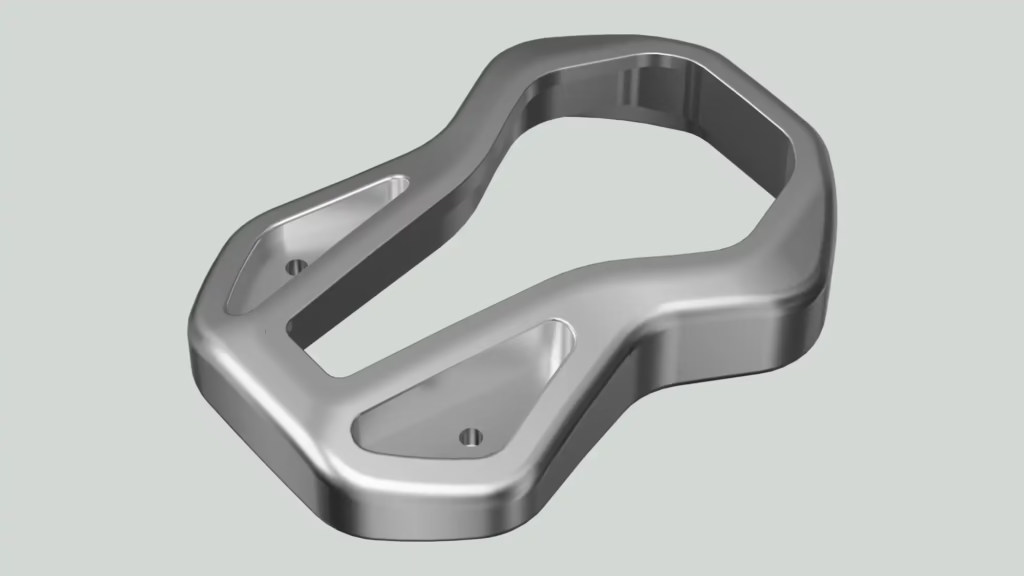

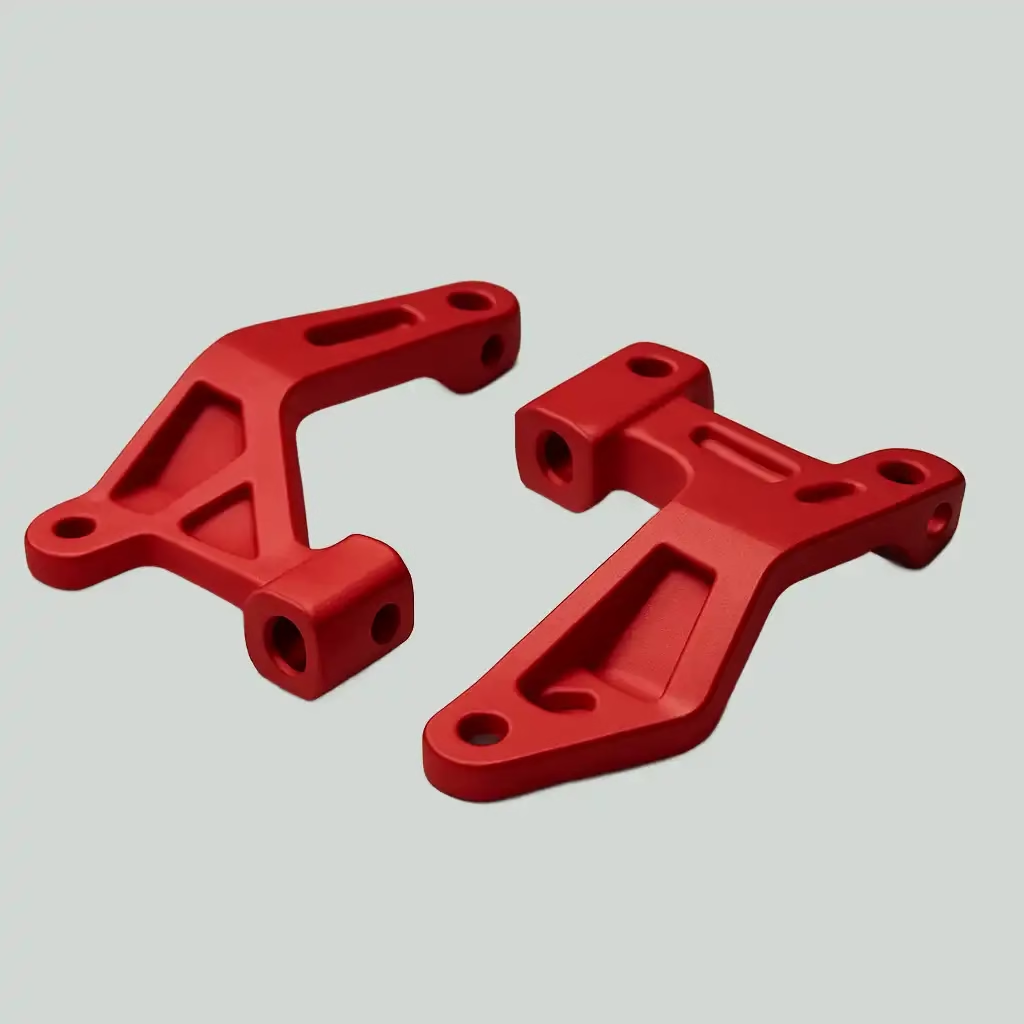

Aluminum High-Precision Machining

Capabilities & Tolerances

Multi axis CNC milling and turning centers

Modern machine shops rely on advanced three-, four-, and five-axis vertical CNC milling centers, as well as CNC horizontal turning centers with live tooling, to achieve the precision and flexibility required for complex aluminum components

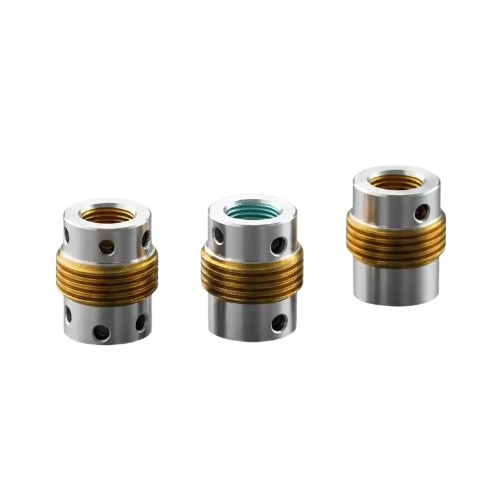

7 axis Swiss-type lathe with bar feeders

For high-volume production of round and cylindrical small parts, six- and seven-axis Swiss-type CNC turning centers with automatic bar feeders are often the machines of choice, delivering consistent quality and tight tolerances.

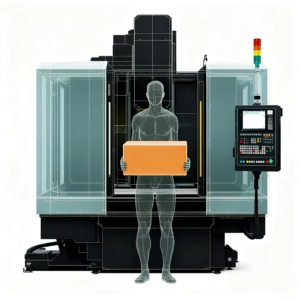

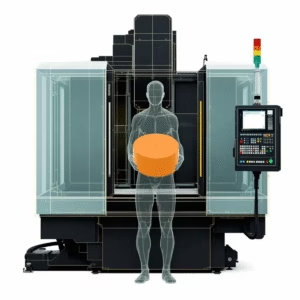

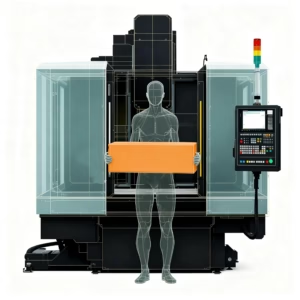

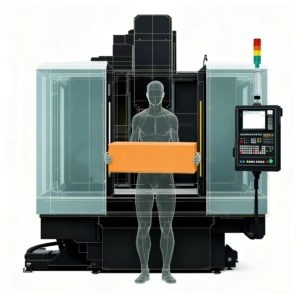

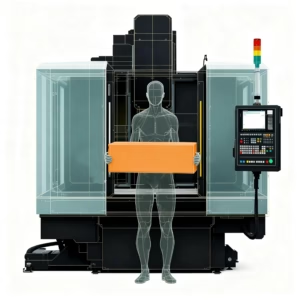

Max CNC Part Envelope

Consult the following guide for a general overview of the practical size limitations for each of our machines. Please note this is for reference only, and exact dimensions are highly dependent on specific part geometry and features. Please contact us to discuss your project in detail.

Our Aluminum CNC Milling Centers

| n | Brand | Model | Type | Envelope |

|---|---|---|---|---|

| 1 | DMG MORI | DMP 70 | Vertical 5-axis mill |  |

| 2 | Haas | DT 1 | Vertical 5-axis mill |  |

| 2 | Haas | DT 1 | Vertical 4-axis mill |  |

| 5 | Haas | DT 2 | Vertical 5-axis mill |  |

| 2 | Haas | DT1 | Vertical 3-axis mill |  |

| 1 | PRIMINER | U500 | Vertical 5-axis mill |  |

| 1 | Haas | UMC-750 | Vertical 5-axis mill |  |

| 3 | Haas | VF-2SS | Vertical 5-axis mill |  |

| 4 | Haas | VF-2SS | Vertical 4-axis mill |  |

| 1 | Haas | VF-2SS | Vertical 3-axis mill |  |

| 2 | Haas | VF-4SS-V | Vertical 5-axis mill |  |

| 1 | Haas | VF-5/40 | Vertical 3-axis mill |  |

| 1 | Haas | VF-5SS | Vertical 3-axis mill |  |

| 4 | Feeler | VMP23A | Vertical 3-axis mill |  |

CNC Turned Aluminum Parts

For all turned parts, the maximum diameter is determined by the size of the chuck or collet, while the minimum for all machines can be as small as 1mm. However, this depends on material and application, so it’s best to speak to our engineers to confirm your project requirements.

| QTY | Brand | Model | Type | Envelope |

|---|---|---|---|---|

| 1 | Tsugami (7-Axis) | SS327- III | Swiss Lathe |  |

| 1 | Tsugami (6-Axis) | SS206 | Swiss Lathe |  |

| 1 | Doosan | LYNX234 | Lathe |  |

| 1 | Haas (with barfeeders) | ST-20Y | Turn Mill |  |

Standard vs. High Tolerance Specs

ISO 2768-1 uses classes f, m, c, and v, where f = fine or the highest general class.

ISO 2768-2 uses classes H, K, L where H is the highest. Even more precise CNC aluminum machining tolerances can be achieved on a feature-by-feature basis. Book a discovery call for a free project review.

Finishing and Treatment

Anodising – Type II and Type III, clear and color dyed available. Best for Series 1XXX, 5XXX, and 6XXX aluminum alloys in various tempers. Provides additional wear resistance and corrosion protection, as well as a basecoat for painting and other surface treatments. Anodized finishes are especially valued in architectural applications for their durability and aesthetic appeal.

Chromate Conversion Coating

Suitable for Series 1XXX, 5XXX, and 6XXX in various tempers. Forms an excellent base for finish painting which yields enhanced corrosion protection and improved aesthetics for custom CNC aluminum parts.

Chrome Plating

Most aluminum alloys can be plated, but they require extensive surface preparation with zinc/copper/nickel base layers.

Priming and Painting

All grades of CNC aluminum can be painted. However, care must be taken with surface preparation, including cleaning, media blasting, sanding, chemical etching. Some aluminum alloys are heat treated before finishing to enhance their mechanical properties and surface quality.

Ready To Start Your Project?

We are a team of technical professionals ready to assist you.

Compliance

Certifications

Our CNC machining aluminum alloys come with full Certificates of Compliance and traceability documentation to help you meet RoHS requirements, including Declarations of Conformity for the EU.

ISO 9001:2015 Certified

You can rely on parts and services that meet the same high standards on every order, reducing risk and surprises

ISO 13485:2016 Certified

Every part is produced under strict documentation and tracking, making audits and recalls easier, faster, and more reliable.

AEO Certification

AEO status gives us priority treatment at borders, reducing delays and helping your shipments move on time

FAQs

Find answers to questions about aluminum CNC machining services and how industries like medical, electronic, agriculture, and consumer products can achieve their goals by working with Procision.

Why is aluminum a popular choice for CNC machining?

Aluminum alloys are an excellent choice for many CNC machining projects due to their unique combination of properties.They can be CNC milled and turned to produce high tolerance parts with fine surface finishes. Aluminum has high strength-to-weight, resists corrosion, and some alloys are perfect for after treatments such as anodising or powder coating.

What’s the best aluminum for CNC machining?

Every alloy has unique metallurgical properties that must be considered before CNC machining. The “best” aluminum is the one that meets your design intent – which includes performance,durability, appearance, etc. Of the major grades, AL-6063-T6 is the easiest to machine, making it an excellent all-purpose choice for products that don’t need the highest levels of performance. AL-7075-T6 is the most difficult to machine, but it’s very strong and rigid and often substitutes for steel in aerospace applications.

What are some other popular aluminum alloys?

AL-1100 is ductile and easily machined but has poor strength so it’s useful for unstressed decorative parts. AL-2XXX is strong but has poor corrosion resistance, used in aerospace components. The 5XXX series is strong and resists corrosion and it’s found in marine and automotive applications.

What factors should I consider when choosing aluminum for CNC machining?

The most important factor to consider is your design intent. What is the part meant to do, and what kind of environment will it be exposed to? There will always be performance trade-offs, so you must consider if corrosion resistance is more important than ultimate strength, or weight more important than elasticity, for example.

Still not sure which aluminum alloy is right for you?

If you’re still not sure which aluminum alloy is right for you book a discovery call and we’ll review your project with you and offer our professional insights to guide your decision.

How do I get a quotation?

Upload your drawings and specifications to the Procision Manufacturing team. We will analyze all the project details and deliver an accurate quotation quickly.

Let's Build What's Next - Together

Whether you’re building one part or one million, the Procision team delivers consistent results — on time, to spec, and built to perform. Request a quote today and discover what a responsive, professional manufacturer can do for you.