A lot of manufacturers claim to offer DFM analysis. They publish blog posts and white papers, hoping to explain what DFM is and how it works.

Unfortunately, most of those definitions are misleading, incomplete, or just plain wrong.

What Is Design for Manufacturability, Really?

- The process (or processes) that will be used to fabricate it

The design intent. For example, the function and purpose the part must fulfill

Why Is Design Intent So Important?

Material Selection and Its Impact on DFM

- Better surface treatment compatibility

- Lower cost

- Greater machinability

- Reduced cycle times

What DFM Is Not

DFM is not

DFM is not dependent on order quantity. It applies equally to one-off prototypes and high-volume production.

DFM does not

DFM is not a cure-all for bad design. It can’t make up for vague specs, incomplete files, or unrealistic expectations.

DFM is also not

DFM is also not a cure-all for bad design. It can’t make up for vague specs, incomplete files, or unrealistic expectations.

What Questions Should a DFM Review Answer?

1. Can the part be made at all?

For example, extreme undercuts on plastic injection molded parts will cause them to lock inside the mold, making it impossible to release them later. Similarly, CNC machining can’t make a feature that isn’t in line-of-site of the cutting tool. Every feature and specification needs to be analyzed with an eye towards feasability.

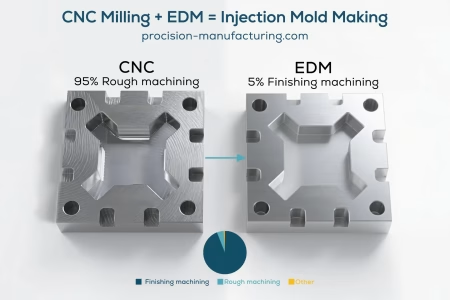

2. What’s the best process to make it?

A good DFM review always looks for the most efficient way to manufacture a design, even if there are potentially several alternatives. As an example, CNC milling wouldn’t be the ideal way to make a cylindrical metal shaft, because it’s slow and expensive. In this case, CNC turning makes much more sense.

3. Is the material suitable for the part’s function?

In reality there may be several materials that could potentially fulfill the design intent, with different benefits and tradeoffs. Among the questions to answer: How long does the part need to last, under what environmental and mechanical conditions, at what cost and difficulty to manufacture? Are there cheaper alternatives that will work just as well? And how would I need to change the design to suit the material?

4. Can we improve manufacturability without compromising performance?

What Are the Benefits of DFM?

- Fewer rejects. By reducing unnecessary critical tolerances or simplifying hard-to-machine features.

- Better aesthetics. Through tweaks to mold parting lines, surface textures, or by recommending better-suited materials (e.g., 6xxx vs. 7xxx aluminum for anodizing).

- Faster throughput. Especially in injection molding, where cooling channel optimization can significantly reduce cycle times.

- Lower total cost. Reduced scrap, shorter runtimes, less tool wear, it all adds up to higher yield and lower spend.

Want to Get DFM Right? Work With the Right Team.

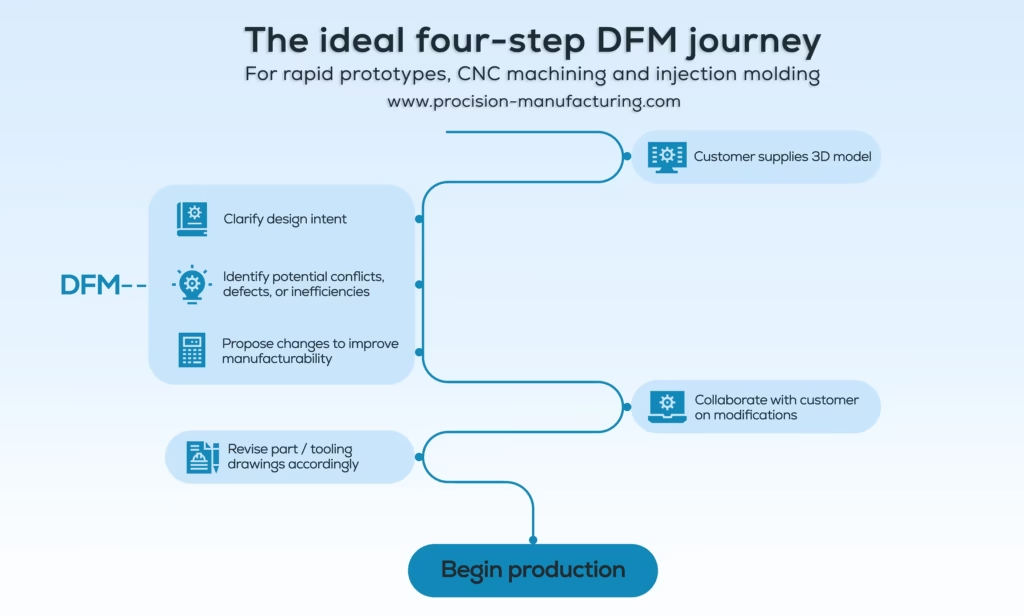

Want to see how it works in practice?