How to Avoid Hidden Risks

When Choosing a CNC Milling Partner

Maybe you’ve been in this situation before You get an online quotation from an overseas supplier of CNC milling services and it’s well within your budget. What’s more, they’ve promised a delivery date that will keep your entire project on schedule and make you look like a hero to your development team.

And then the dreaded emails start showing up, with one excuse after another: unexpected machine downtime; supply chain interruptions; delayed shipments; parts out of tolerance. Now you’re scrambling to find a milling service provider you can trust to protect your costs and keep your project on schedule for its duration – not just next quarter.

For procurement managers, designers, and engineers in the product develop industry tasked with sourcing precision CNC milled parts, the challenge is clear: how can you identify a vendor who won’t cut corners or fail under pressure?

Below, we outline the four defining characteristics of CNC milling service providers who consistently deliver superior results and how to spot red flags before your project goes sideways.

Book A Discovery Call

Not ready for a quote? No worries, Book a quick call with the sales rep in your area.

Our Team

Sales Director Mathieu Windsor

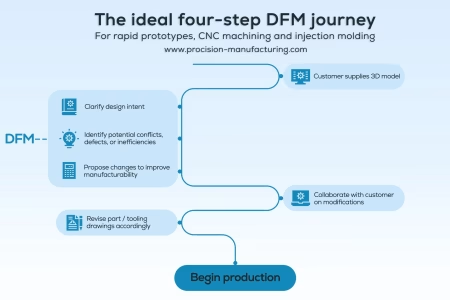

No.1 Proactive DFM Support and Application-Focused Engineering

Some CNC machining vendors promise speed, but shortcut the design review process. They’ll quote anything you upload, no questions asked. That may sound convenient at first, but skipping proper Design for Manufacturability (DFM) analysis is a recipe for a host of problems, including:

- Excessive part costs due to avoidable complexity

- Dimensional drift or tolerance stack-up during production

- Overlooked undercuts, unsupported thin walls, or problematic geometries

- Missed opportunities to reduce setup time or tool changes

A high-performance custom CNC milling supplier will carefully review your design files and technical documentation. This ensures all technical requirements are clearly communicated and manufacturability is fully assessed before production begins. Here’s what a thorough DFM and engineering support process should include:

1. Review your 3D model and technical drawings for clarity and completeness;

2. Check for missing or ambiguous tolerances, threads, or finishes;

3. Identify overlooked undercuts and problematic geometries that may be inaccessible to the cutting tool;

4. Confirm material selection and stock availability;

5. Assess fixturing and workholding requirements;

6. Provide design feedback to improve manufacturability;

7. Flagging risks such as visible tool marks, potentially sharp edges, thin walls, or unsupported features that could compromise part quality or safety.

A robust DFM review by engineers helps you avoid surprises, reduce costs, and get parts that meet your exact requirements.

This level of engagement reflects a true partnership mentality, not just job-shop fulfillment. It also protects you from costly surprises after your PO is signed.

No. 2 Verified Materials with Full Traceability and Compliance

CNC milling is often used to make products that must perform under mechanical stress, thermal cycling, exposure to chemicals, or tight dimensional constraints.

In these scenarios, material integrity is non-negotiable. Sourcing the correct material stock is essential, and the ability to fulfill custom requests through a material drop down or similar system ensures you get the exact CNC milling materials required for your application.

Yet many low-cost suppliers treat material sourcing as an afterthought. Some may even substitute less expensive alloys or resins – either due to convenience or to pad margins – assuming you won’t test or trace the inputs. This can lead to:

- Milled parts that fail under load

- Incompatibility with downstream processes like welding or anodizing

- Regulatory compliance issues in industries such as aerospace, defense, and medical.

Top-tier CNC suppliers mitigate these risks by investing in robust material verification protocols. They typically:

- Source from reputable, vetted suppliers only

- Maintain mill certs and material test reports(MTRs) linked to each job

- Use positive material identification (PMI)tools when needed

- Offer full material traceability, especially critical for FDA or ISO 13485 applications

This level of transparency supports your own quality system, giving you confidence that the part you received is made from exactly the material you specified – nothing less.

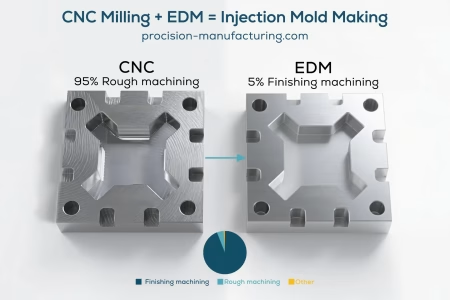

No.3 Tight Process Control and Facility-Driven Consistency

Precision CNC machining isn’t just about good CAM programming or machine specs. It’s about process stability—and that depends on everything from machine setup to environmental controls.

Without robust process control, even a “simple” aluminum bracket can vary from one batch to the next. Here’s what serious CNC machine shops do to maintain consistency for high tolerance fabrication.

Climate-Controlled Machining Environments

Changes in ambient temperature can cause materials and machines to expand or contract, impacting critical dimensions. Leading suppliers control for this.

Vibration-Isolated Machine Foundations

CNC machines must sit on reinforced, stable foundations to maintain accuracy under dynamic loads.

Repeatable Workholding and Setup Procedures

Reliable fixturing and datums are key to minimizing variation across production runs.

Calibration Schedules and Preventive Maintenance

A neglected machine can easily drift out of spec. Good shops have documented PM schedules and gauge calibration systems in place.

Finally, credible suppliers will often hold ISO 9001, AS9100, or ISO 13485 certifications, signaling a mature quality management system with an emphasis on root cause analysis and continuous improvement.

No.4 Transparent Communication and Real-Time Collaboration

Even with the best engineering and planning, custom manufacturing projects sometimes encounter hiccups: a tool breaks unexpectedly, a raw material is delayed, a critical feature is misinterpreted. These situations aren’t inherently problematic – what matters is how your supplier responds.

Poor communication can turn a small issue into a major cost. The worst-case scenarios include:

- Late disclosures about missed delivery dates

- Scope changes that weren’t discussed upfront

- Lack of responsiveness, leaving you in the dark during production

- Finger-pointing when something goes wrong

In contrast, a great CNC supplier acts like an extension of your team. They:

- Proactively raise issues before they escalate

- Provide clear, accurate updates on part status

- Share photos, inspection reports, and other documentation as the job progresses

- Take ownership when problems arise and help you find solutions fast

This isn’t just good customer service. It’s critical risk management, especially for programs with tight deadlines, regulatory oversight, or cross-functional stakeholders.

Final Thought: CNC Quality Isn’t Accidental – It’s Engineered

If your supplier is serious about quality, you’ll see it in everything they do: from quoting and DFM to final part packaging and delivery. They’ll have a repeatable, controlled, and collaborative approach – not just a fast machine and a flashy website.

At Procision Manufacturing, our commitment to quality is built into every part we make. Whether you need five custom prototype units or 50,000 production parts, we bring world-class process control, engineering expertise, and transparent communication to the table.

Let’s build something better together.

Upload your CAD files for a free, no-obligation quotation for the first button.

Or book a discovery call to discuss your next CNC milling project.